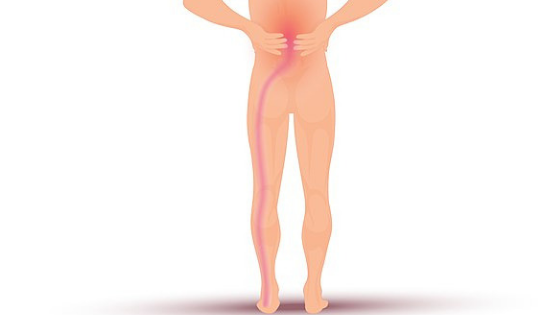

The common problem with prosthetic limb user is pain at the interface between their residual limb (the amputation site) and their artificial limb. But fortunately this problem can be solved with new way of designing a tailor-made prosthetic liners.

Following an amputation, a person’s residual limb constantly changes in shape and size during the healing process, which can last between 12-18 months. This variation can result in the liner fitting poorly, leading to tissue damage, causing pain and discomfort for amputees.

This is exacerbated by patient activity levels and environmental conditions such as hot weather. This discomfort can lead to patients abandoning their prosthesis and rehabilitation regime, instead of being forced to rely on a wheelchair.

Tailor-made prosthetic liners could help more amputees walk again

According to research published by the University of Bath on Friday 21 June 2019, they have developed a new way of designing and manufacturing bespoke prosthetic liners, in less than a day.

It is an combination of advances in computer science with an innovative manufacturing process to create affordable new personalised prosthetic liners for lower limb amputees.

Let us try to understand how this tailor made prosthetic liners can change life of an amputee and how it is possible.

Science behind tailor-made prosthetic liners

The research was a multidisciplinary project with experts of the following department from the University of Bath were involved.

- Department of Mechanical Engineering,

- Department for Health and Centre for the Analysis of Motion,

- Entertainment Research and Applications (CAMERA),

The first step was to precisely scan the 3D shape of amputee’s residuum using a state-of-the-art scanner which quickly captures 3D shape. The scanned data is then used to create a full digital model of the residuum.

The digital model is subsequently used to design a personalized liner. The liner is then manufactured using a cryogenic machining technique, negating the need for complex and time consuming moulds.

Lecturer in the Department of Mechanical Engineering, Dr Vimal Dhokia, said: “There’s a window of around 18 months where an amputee decides whether to use prosthetics to learn to walk again or use a wheelchair.

“Unfortunately this is a time the residuum changes in size and shape as part of the healing process, making it difficult to get a good fitting.

“Our technology will help achieve a comfortable fit for the patient and really make a difference in helping them walk again and improve their quality of life.”

They further studied the effectiveness of the prosthetic liner using sensors in the prosthetic, alongside the motion capture technology to analyse the movement when he walks.

Dr Elena Seminati, Lecturer in Clinical Biomechanics at the University, said: “We’ve found this new liner reduces the pressure on the stump significantly, reducing the risk of skin damage and making it more comfortable to walk.

“We hope this technology will help many amputees in the future.”

The good thing is the entire process from 3D scanning to designing the liner and fittings only takes a day.

Case study

Resource

- Tailor-made prosthetic liners could help more amputees walk again (research published on 21 June 2019, by University of Bath): https://www.bath.ac.uk/announcements/tailor-made-prosthetic-liners-could-help-more-amputees-walk-again/

The author is a physiotherapist who has been practising for the last 17 years. He holds a Bachelor's in Physiotherapy (BPT) from SVNIRTAR (Swami Vivekananda National Institute of Rehabilitation and Research), one of the prestigious physiotherapy schools in India.

Whatever he learns dealing with his patient, he shares it with the world through blogs and e-books. He also owns a YouTube channel, "Sunit Physiotherapist" with over 8 lakh active subscribers. Here, he shares everything he gets to learn serving the patient.

Pingback: What's Waddling Gait? Causes, Physiotherapy Treatment - Physiosunit

Pingback: Circumduction gait: Causes, muscle weakness, treatment : Physiosunit